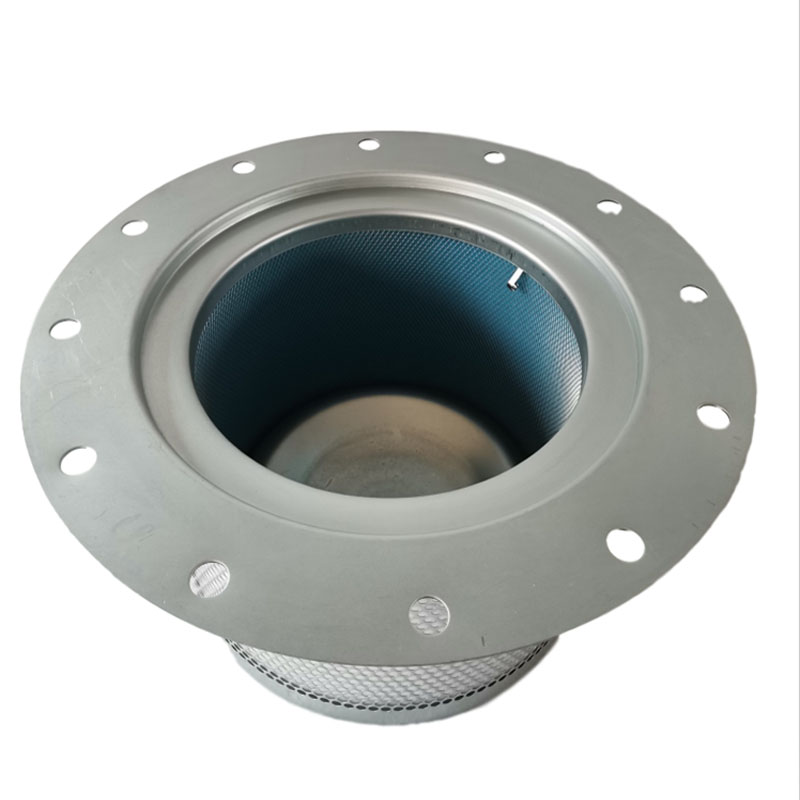

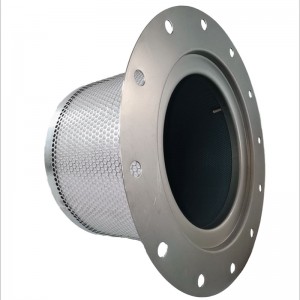

Wholesale 1623051600 Separator Filter Compressor Manufacturers

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

The Atlas Copco oil separator 1623051600 is an efficient oil-gas separation component specially designed for screw-type air compressors. It uses ultra-fine glass fiber filter material and multi-level filter material distribution technology to control the residual oil content in compressed air to ≤ 3 ppm, significantly reducing equipment maintenance costs. Its galvanized anti-rust structural components and double-sided bonding process ensure stable operation in a 150℃ high-temperature and highly corrosive environment. The electrostatic diversion device further guarantees the safety of the equipment. It is suitable for Atlas screw air compressors in industrial manufacturing, energy extraction and other fields, especially for high-load continuous operation environments.

Core Selling Points and Technical Parameters

Ultra-low Residual Oil Control: Utilizing gradient density glass fiber filter media, the residual oil content in compressed air is controlled to ≤2 ppm (actual measured value), which is superior to industry standards.

Adaptive Pressure Difference Design: The galvanized steel mesh support structure reduces the initial pressure difference by 15% and extends the filter element service life to 3,500 hours (based on ISO 8573 - 4 testing).

Multi - environment Compatibility: It has passed the verification under extreme temperatures ranging from -20°C to 160°C and is compatible with Atlas D/S series main engines and mineral oil/synthetic lubricating oil.

User Value Scenarios

Energy Saving and Consumption Reduction: For every 0.05 MPa reduction in pressure difference, approximately 1,200 yuan can be saved on annual electricity costs (taking a 75 kW model as an example).

Simplified Maintenance: The patented electrostatic conduction technology reduces sludge accumulation and extends the maintenance cycle by 20%.

Compliance Assurance: It is suitable for machining equipment and the food packaging industry.

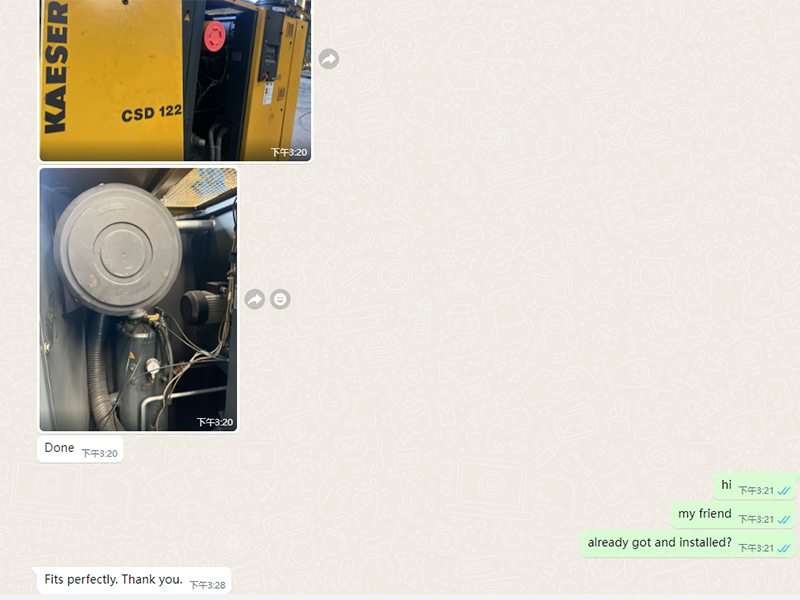

Customer Feedback

.jpg)

Buyer evaluation