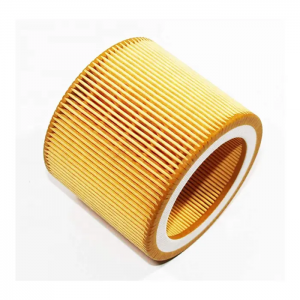

Wholesale Compressor Filter Element 1613900100 Supplier

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

The air filter of a screw air compressor is the first line of defense for the compression system. It catches impurities like dust and particles in the inhaled air to make sure the air entering the main unit is clean. This not only extends the lifespan of the oil filter, oil-gas separator, and lubricating oil, but also prevents foreign objects from damaging the delicate main unit components, avoiding serious problems like the main unit seizing up or getting scrapped.

The filter elements of air filters usually use the following materials:

1.High-purity imported filter paper: The mainstream choice, featuring a multi-layer fiber structure, capable of intercepting particles larger than 1 micron, with a dust removal efficiency of up to 98%. Some high-end models may use glass fiber material, further enhancing the filtering accuracy and high-temperature resistance.

2.Waterproof treatment layer: The surface of the filter paper is often coated with a waterproof layer to prevent the filter element from getting damp and clogged in humid environments, which would affect the suction efficiency.

3.Structural support components: The outer shell is mostly made of metal (such as aluminum alloy) or engineering plastics to ensure sealing and pressure resistance; the internal part may use a stainless steel frame to reinforce the filter element.

In addition, activated carbon composite filter elements can be used in special scenarios (such as in the chemical industry) to adsorb oil vapors or odors. The replacement cycle of the filter element is usually 8,000 hours or 1 year, but it needs to be adjusted according to the dust concentration in the environment. If the pressure difference exceeds 0.7 bar, it is necessary to replace it immediately. Poor-quality filter elements can lead to increased energy consumption, intensified wear on the main unit, and even cause chain failures such as excessive exhaust temperature.

Contact Us:Xinxiang Jinyu Filter Industry Co.,Ltd

Website:https://xxjyly.en.alibaba.com

https://www.xxjinyufilter.com

Whatsapp/wechat:+86--15993089106

Email: sales01@xxjinyufilter.com

Upgrade your air compressor system with the best in the business.

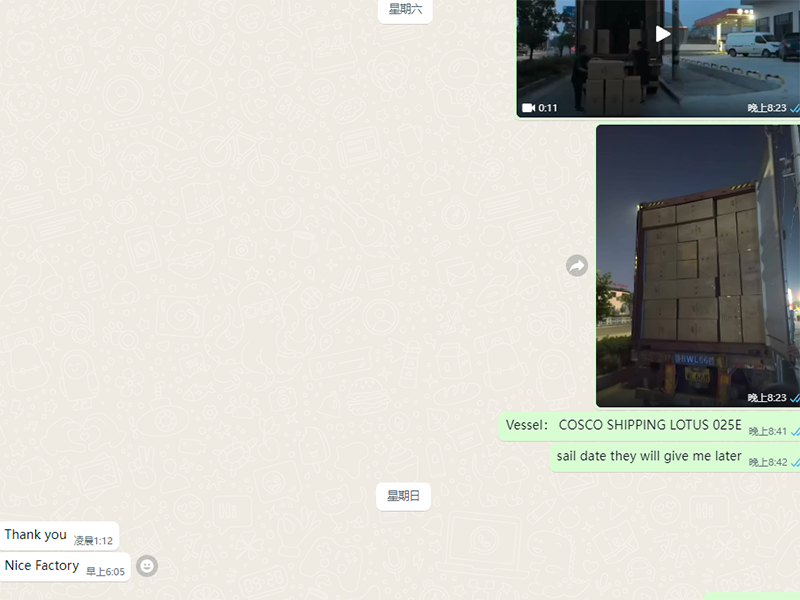

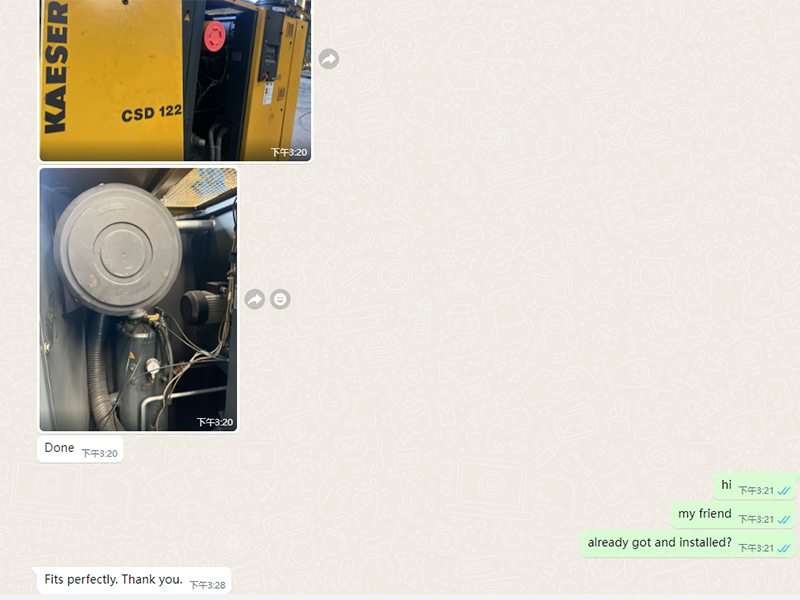

Customer Feedback

.jpg)

Buyer evaluation