CONTACT US !!!

Wholesale Compressor Oil Separator 92890334 Filter

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

The oil-gas separation filter element 92890334 is a common air compressor accessory, primarily used for separating the lubricating oil from compressed air to ensure the cleanliness of the output air. This model is typically applicable to oil-water separators or oil-gas separators with M22 or M30 interfaces and serves as a crucial component in the maintenance of industrial equipment.

The installation steps for the oil and gas separation filter element are as follows:

Equipment shutdown and power outage: First, stop the operation of the screw air compressor and cut off the power supply. Hang a warning sign at the power switch stating "Work in progress, do not close the switch" to prevent accidental startup.

Release system pressure: Open the drain valve of the air compressor and completely release the compressed air and residual oil and gas in the system to avoid injury caused by high-pressure gas spraying during disassembly.

Remove the outer cover: Use appropriate tools, such as wrenches, to sequentially unscrew the bolts that fix the upper cover of the oil and gas tank. Carefully remove the upper cover and place it in a clean and stable location to prevent damage to the sealing surface due to collision.

Remove the old filter element: Observe the position and fixation method of the old filter element, and carefully remove the old filter element from the oil and gas tank. During the removal process, pay attention to the position of the return oil pipe to avoid blocking or damaging it. At the same time, check if there are impurities, oil stains, etc. inside the oil and gas tank. If necessary, clean it.

Inspect the new filter element: After obtaining the new oil and gas separation filter element, first check if the appearance of the filter element is damaged, if the identification information on the filter element is correct, and ensure that it is a filter element suitable for this type of screw air compressor.

Determine the installation direction: There will be a clear arrow on the filter element, and this arrow indicates the direction of the airflow. Place the new filter element in the oil and gas tank in the correct direction to ensure that the filter element is in the correct position relative to the oil and gas tank.

Handle the sealing components: Check if the sealing ring of the filter element is intact. If damaged, replace it promptly. Apply a thin layer of lubricating oil on the sealing ring so as to reduce friction during installation and ensure the sealing effect.

Install the upper cover: Carefully place the oil and gas tank upper cover in its original position to ensure that the upper cover is fully sealed against the sealing surface of the oil and gas tank. Then, tighten the fixing bolts in a diagonal sequence to ensure uniform force on the upper cover and prevent air leakage.

Start-up check: After installation, first open the outlet valve of the air compressor, then connect the power supply and start the air compressor. Carefully observe the operating status of the air compressor, check if there are any oil or gas leakage at the interface. At the same time, pay attention to observing whether the pressure, temperature, etc. of the air compressor are normal to ensure the correct installation of the oil and gas separation filter element and the stable operation of the equipment.

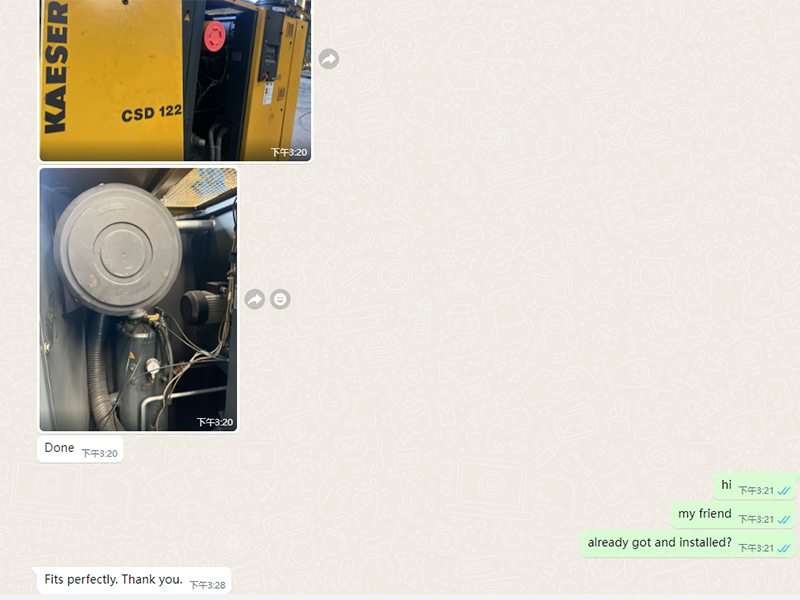

Customer Feedback

.jpg)

Buyer evaluation