Factory Price Air Compressor Separator Filter 88181755 Oil Separator for Ingersoll Rand Separator Replace

Product Description

The basic steps of air compressor oil production are as follows:

Step 1. Prepare raw materials

The main components of air compressor oil are lubricating oil and additives. The selection of lubricating oil should be selected according to different application environments and use requirements. The additives also need to be selected according to different performance requirements.

Step 2 Mix

According to the specific formula, the lubricating oil and additives are mixed in a certain proportion, while stirring and heating to make it fully amixed.

Step 3: Filter

Filtration is a key step in ensuring product quality. The mixture of lubricating oil and additives needs to go through a specific filtration process to remove impurities and particles in order to ensure a clean and uniform product.

Step 4: Separation

The mixture is centrifuged to separate lubricating oils and additives of different densities.

Step 5: Packing

The oil content of the air compressor can meet the needs of different automobiles and machinery. The produced oil will be packaged, stored and transported in an appropriate way to ensure that its quality and performance are not affected.

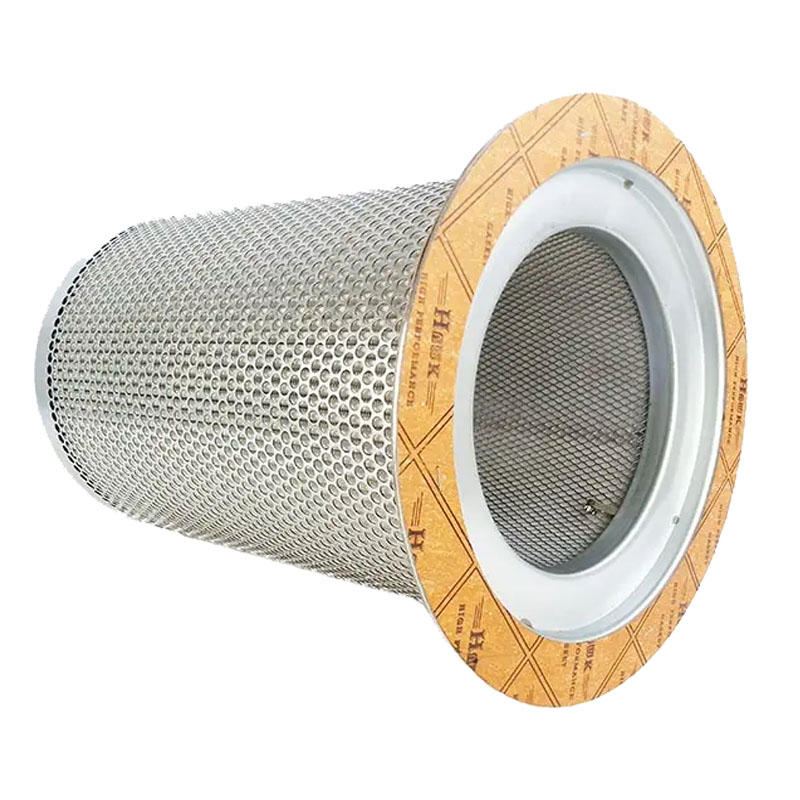

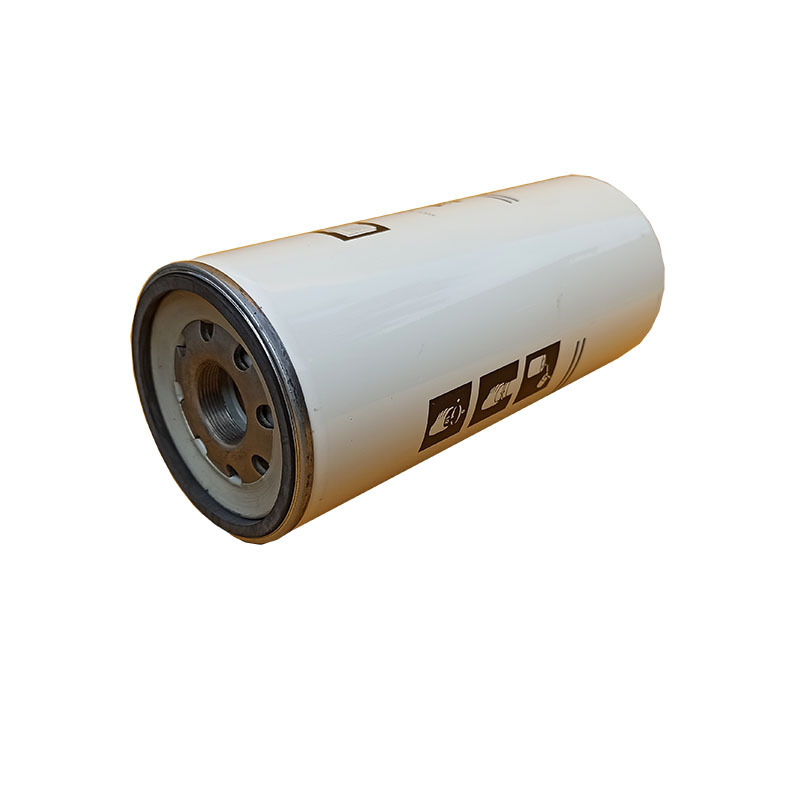

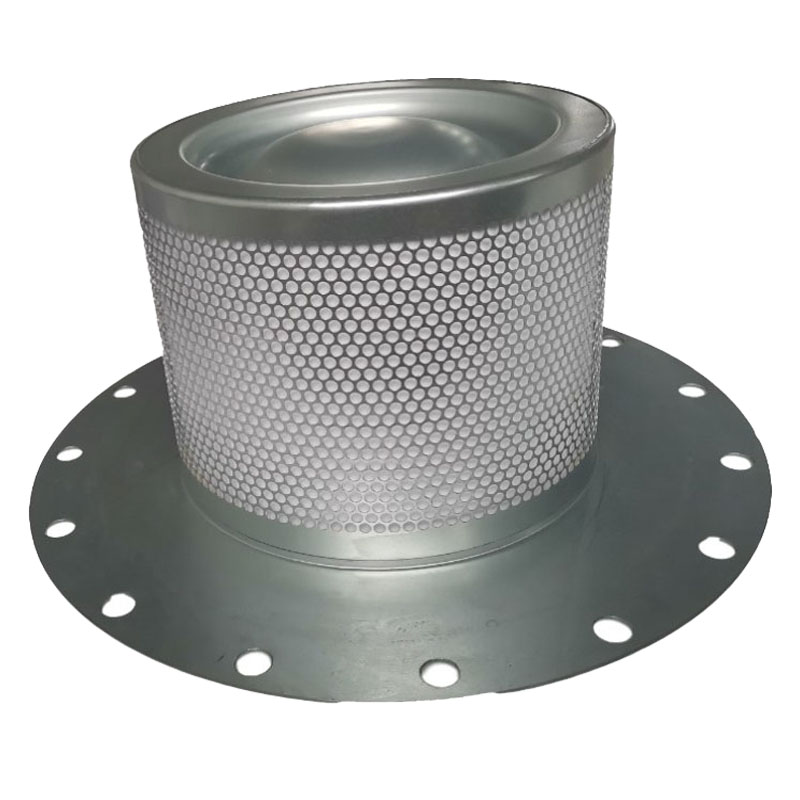

The oil and gas separator is a key component responsible for removing oil particles before compressed air is released into the system. It works on the coalescence principle, which separates the oil droplets from the air stream. The oil separation filter consists of multiple layers of dedicated media that facilitate the separation process.

The first layer of the oil and gas separation filter is usually the pre-filter, which traps larger oil droplets and prevents them from entering the main filter. The pre-filter extends the service life and efficiency of the main filter, allowing it to operate optimally. The main filter is usually a coalescing filter element, which is the core of the oil and gas separator.

The coalescing filter element consists of a network of tiny fibers that create a zigzag path for compressed air. As air flows through these fibers, oil droplets gradually accumulate and merge to form larger droplets. These larger droplets then settle down due to gravity and eventually drain into the separator's collecting tank.

The efficiency of oil and gas separation filters depends on a number of factors, such as the design of the filter element, the filter medium used, and the flow rate of compressed air. The design of the filter element ensures that the air passes through the maximum surface area, thus maximizing the interaction between the oil droplets and the filter medium.

Maintenance of the oil and gas separation filter is essential to ensure its proper operation. The filter element must be checked and replaced regularly to prevent clogging and pressure drop.