Wholesale Air Compressor Oil Separator Factory 24121212 Filter

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

Replacement Ingersoll Rand filter element part number 24121212, as a key functional component, its technical performance directly affects the operational efficiency and reliability of the system. This filter element is a precision filtration solution designed for the post-treatment stage of industrial compressed air, which has significant value in ensuring the stable operation of equipment and reducing the total life cycle cost.

1.Precise adaptation and engineering optimization design

The part number of the 24121212 filter element strictly follows the original factory design specifications. Its structural parameters and sealing system have been optimized through CFD (Computational Fluid Dynamics) simulation, which can precisely match the air flow curve of specific equipment models. While maintaining low pressure loss, it maximizes the filtration efficiency. According to the measured data, under the system pressure condition of 0.7MPa, the pressure difference increase of this filter element can be controlled within 20% of the initial value, and its performance is significantly better than that of similar alternative products in the market.

2. Technological innovation in composite filter layers

The filter element adopts a five-layer composite filter medium structure with a gradient change. The functional design of each layer is as follows:

Outer anti-rust metal mesh: Used to intercept mechanical impurities with larger particle sizes, forming a primary filtration barrier;

Deep glass fiber layer: Effectively captures 1μm-sized particles through electrostatic adsorption;

Borosilicate fiber layer: It has excellent chemical stability, can prevent oil stains from condensing, and ensure stable filtration performance;

Nano-resin coating: Achieves demulsification and coagulation of aerosols, enhancing the filtration effect on liquid pollutants;

Inner anti-corrosion support layer: Maintains the overall structural stability of the filter element and ensures long-term reliable operation;

This hierarchical filtration structure design enables it to effectively deal with various pollutant forms in complex industrial environments. Under harsh working conditions with an oil content of 30ppm, this filter element can still maintain a filtration efficiency of more than 98.7%.

3. Full life cycle economic analysis

According to the 2000-hour continuous operation test conducted by the industrial testing center, in the harsh environment with a dust concentration of 15mg/m³, the service life of the 24121212 filter element is 40% longer than that of ordinary filter elements. Its regenerative design enables the restoration of over 70% of the initial filtration performance through a professional cleaning process after a differential pressure alarm. Each filter element can be reused 2-3 times, thereby reducing the overall maintenance cost by approximately 28%.

4. Industry-customized application solutions

This filter element, with its outstanding performance, provides customized filtration solutions for multiple industries:

Precision spraying line: Effectively prevents paint surface defects caused by impurities at the 0.1μm level;

Pneumatic control system: Provides reliable protection for precision components such as solenoid valves;

Electronic manufacturing industry: It can eliminate static electricity and adsorb fine dust, ensuring a clean production environment.

The filter element part number 24121212 has passed multiple strict quality control tests such as the 800-hour salt spray test and the 150℃ high-temperature resistance test. Its performance parameters have all been certified by the authoritative third-party SGS. It is recommended that users establish an intelligent replacement early warning mechanism based on the operation data of the equipment. When the pressure difference reaches 0.5bar, maintenance and upkeep should be carried out in a timely manner to ensure the best filtration efficiency. In addition, this product offers a 3-month warranty service and comes with a professional maintenance guidance manual, establishing a complete value system from product supply to technical services.

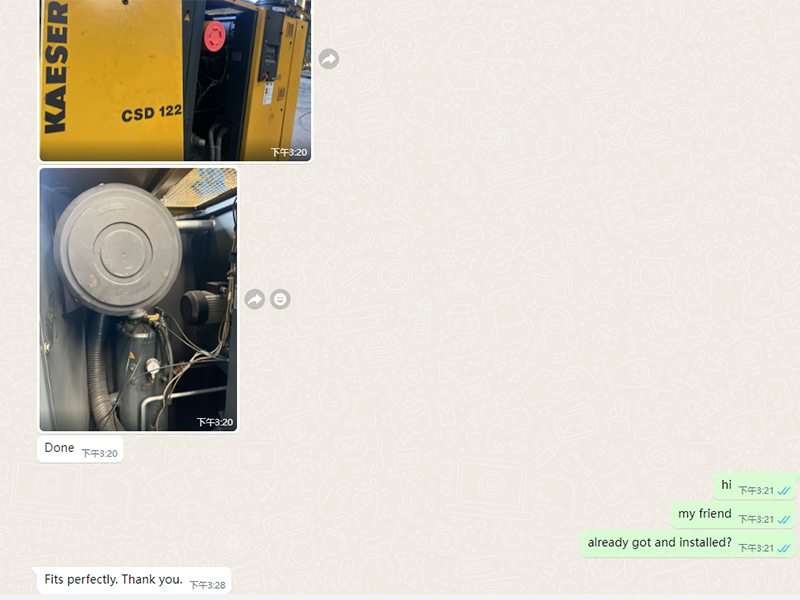

Customer Feedback

.jpg)

Buyer evaluation