Wholesale Separator Filter Compressor Supplier 6.3623.0

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

I. Product Overview

The compressor oil mist filter element is the core component of the compressor oil separation system, specially designed to efficiently separate oil droplets in compressed air. It uses multi-layer composite filter materials (such as glass fiber or stainless steel framework), with its micropores finely down to 0.01 micrometers, ensuring that the oil content in the outlet air is less than 3PPM (one part per million), significantly improving the purity of compressed air. This product is widely used in manufacturing, automotive maintenance, energy and other fields, and is a key consumable for ensuring the long-term operation of equipment.

II. Core Technology and Performance Parameters

Filter Efficiency: Over 99% oil mist retention rate, supports continuous high-pressure conditions (with a maximum tolerance of 3 atmospheres);

Intelligent Protection: Integrated bypass valve (automatically opens when pressure exceeds limit) and check valve (prevents oil from flowing back during shutdown), providing dual safety guarantees for the system;

Life Index: Standard working conditions, the service life is 3000-6000 hours, reducing the frequency of replacement;

Material Selection: Provides three filter material options: PET/PP synthetic fibers (high chemical stability), metal mesh (high temperature resistance), and paper (economical type), suitable for different environmental requirements.

III. Product Types and Applicable Scenarios

Oil and Gas Separation Filter Element: Mainly used in the post-treatment stage, suitable for screw-type and piston-type compressors;

Inlet Filter Element: Pre-protection, intercepting particles larger than 5 micrometers, protecting the compressor intake system;

Oil Filter Element: Deeply purifying circulating lubricating oil, reducing metal wear debris, and extending equipment lifespan.

IV. Innovative Advantages and Typical Cases

Structural Optimization: The tower-shaped pleated design increases the filtration area by 2 times, suitable for high-humidity environments;

Intelligent Monitoring: Optional IoT pressure sensor, providing real-time feedback on filter element status, predicting maintenance intervals (a car manufacturer measured the maintenance interval extended to 4500 hours);

Lightweight Solution: Aluminum alloy housing accounts for 45% of the weight, carbon fiber filter element reduces weight by 30%, facilitating installation and maintenance.

V. Application Suggestions

It is recommended to replace the filter element every 4000 hours or when the system pressure difference exceeds 0.5MPa. For high-dust environments, a pre-filter can be used in combination to further extend the filter element lifespan. This product is compatible with mainstream compressor brands (such as Atlas Copco, Ingersoll Rand), and customized services are provided to meet special working condition requirements.

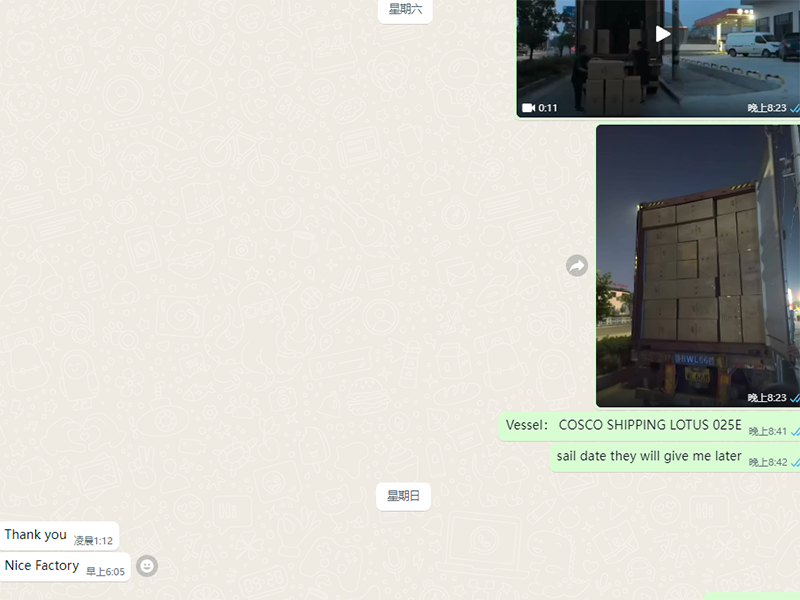

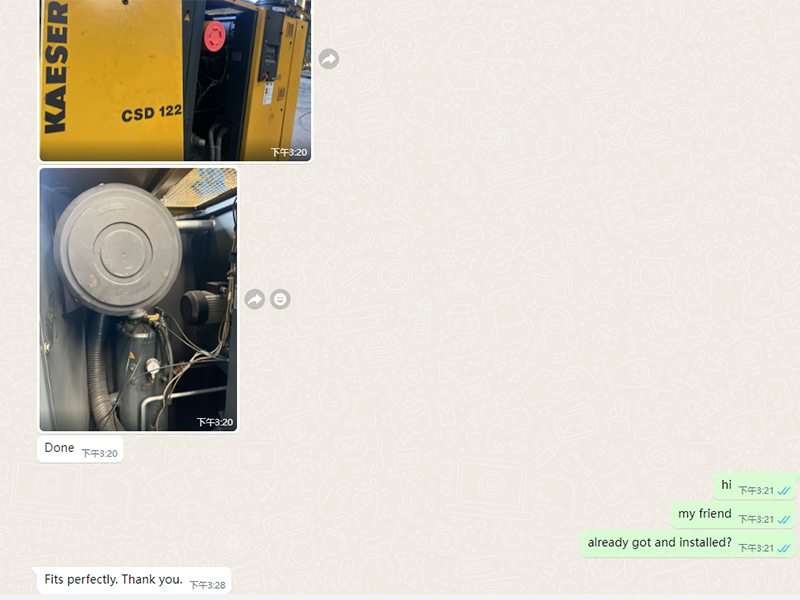

Customer Feedback

.jpg)

Buyer evaluation