Factory Price Screw Air Compressor Coolant Filter 250031-850 Oil Filter for Sullair Filters Replacement

Product Description

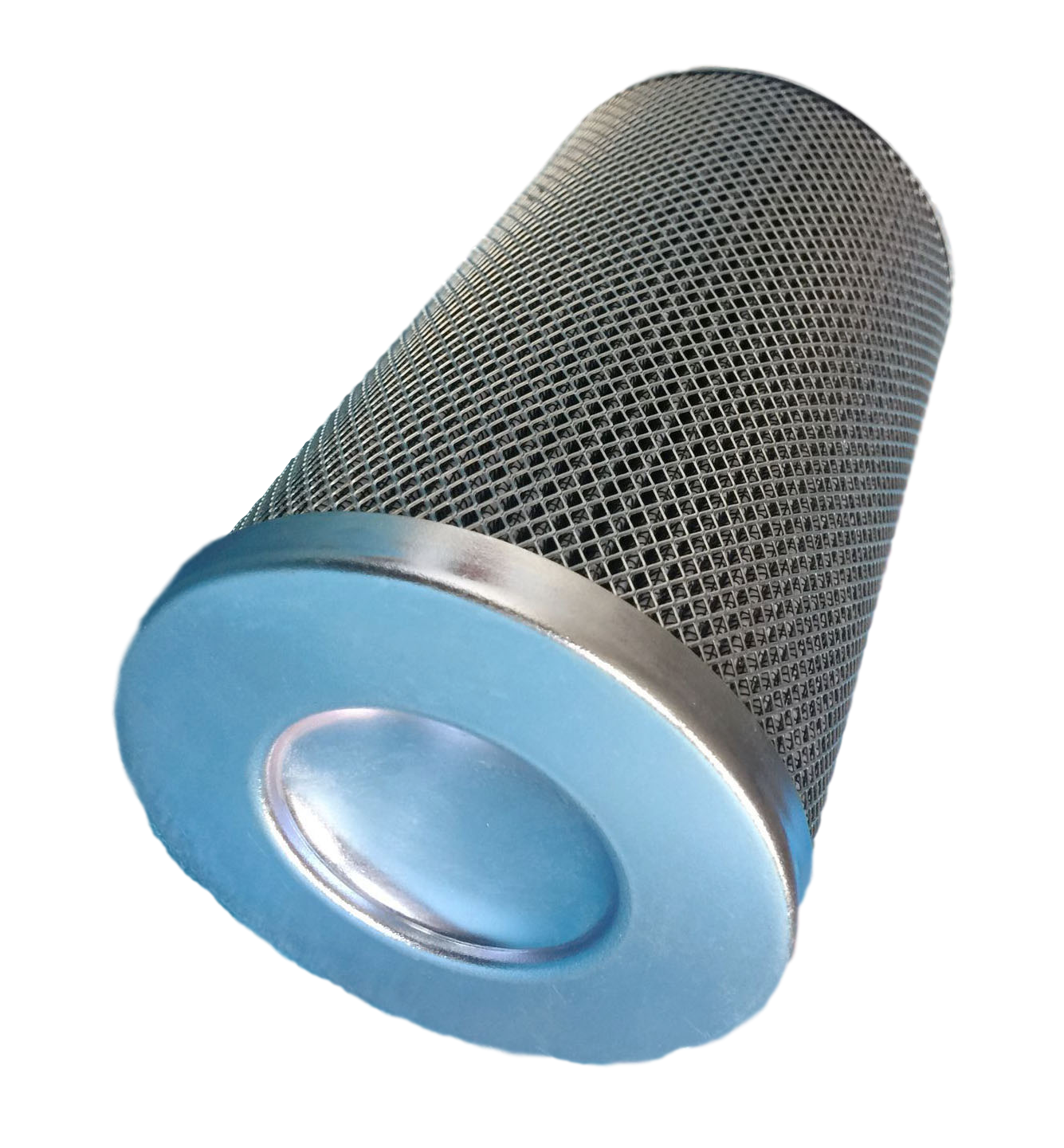

Hydraulic oil filtration is through physical filtration and chemical adsorption to remove impurities, particles and pollutants in the hydraulic system. It usually consists of a filter medium and a shell.

The filtration medium of hydraulic oil filters usually uses fiber materials, such as paper, fabric or wire mesh, which have different filtration levels and fineness. When the hydraulic oil passes through the filter element, the filter medium will capture the particles and impurities in it, so that it cannot enter the hydraulic system.

The shell of the hydraulic oil filter usually has an inlet port and an outlet port, and the hydraulic oil flows into the filter element from the inlet, is filtered inside the filter element, and then flows out of the outlet. The housing also has a pressure relief valve to protect the filter element from failure caused by exceeding its capacity.

When the filter medium of the hydraulic oil filter is gradually blocked by pollutants, the pressure difference of the filter element will increase. The hydraulic system is usually equipped with a differential pressure warning device, which sends a warning signal when the differential pressure exceeds the preset value, indicating the need to replace the filter element.

Regular maintenance and replacement of hydraulic oil filters is essential. Over time, filters can accumulate large amounts of pollutants, reducing their efficiency. By preventing contaminants from entering the system, hydraulic oil filters improve the efficiency and productivity of hydraulic machinery or equipment, ensuring smooth operation of equipment.

The hydraulic oil filter should be changed according to the manufacturer's recommendations. However, as a general guideline, it is typically recommended to change the hydraulic oil filter every 500 to 1000 hours of equipment operation or at least once a year, whichever comes first. Additionally, it is important to regularly inspect the filter for signs of wear or clogging, and replace it if necessary, to ensure proper functioning of the hydraulic system.